| INDUSTRIAL FILTRATION : EDGE FILTER |

|

TECHNICAL FEATURES:

- Automatic metal-edge filters are suitable for all applications where low or high-viscsity liquids or pastes have to be filtered and homogenized.

- These compact inline filter systems can be designed for semi or fully automatic cleaning. The system is cleaned by rotating the filter cartridge against scraper.

ADVANTAGES:

- Extended filter service life due to the use of a cleanable element.

- Cleaning is possible without interruption filteration.

- Precise separation quality in accordance with the metal-edge principle.

- Sturdy filter cartridge made of triangular spring steel on a rugged core element.

- Efficient filter cleaning assures maximum process stability.

- Solid consruction and high-quality materials for a long service life.

- Material variants open up a wide range of application.

- Easy maintenance.

FILTER DATA

Edge filter type |

40 mesh & 60 mesh |

Operation pressure |

20 bar

(other pressure rating on request) |

Operation temp |

65 Dig. C |

Materials |

- Body : aluminum

- Element : SS 316

- Hard-anodized OR powder Coating

- Seal : Rubber (Viton)

|

End connection |

11/2” BSP (Female) |

* Other types available on request!

* Technical data is subject to change without notice! |

|

|

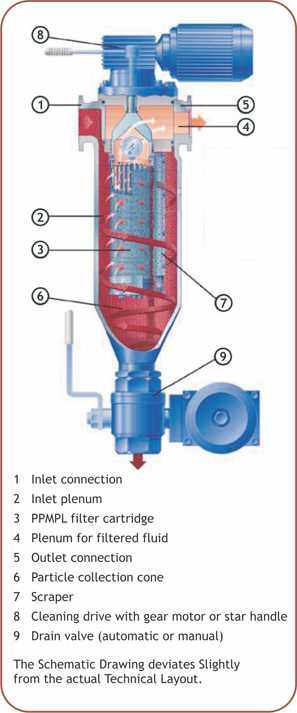

Operating Principle:

- The PPMPL metal-edge filter system is used to filter and homogenize a wide range of liquids and pastes.

- This compact, inline filter system consumes no filter material, which means there is also no need for subsequent disposal. The filter is cleaned either automatically or semi-automatically without interrupting operation.

- The concentrated solids are drained off simple by opening the system for a short time.

- The medium to be cleaned is guided into the filter housing under pressure or in suction mode. It flows inward.

- The filter is cleaned either when a preset differential pressure limit is reached or after a specified cycle time elapses. The PPMPL filter cartridge is rotated against scraper for this purpose. The special gap geometry of the filter cartridge guarantees efficient cleaning.

- The particles or agglomerates are skimmed from the surface and settle in the collection cone.

- The residue that has settled in the collection cone can be emptied via the drain valve either when the machine is at a standstill or during filtration.

|

|

|

|

|